HOMER Pro 3.15

![]()

The Hydrogen Tank page contains the cost and performance inputs for the hydrogen storage tank.

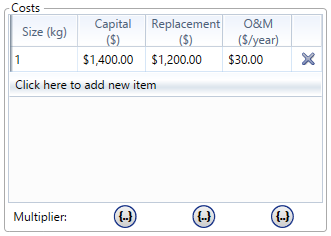

Costs

In the hydrogen tank Costs table, enter the hydrogen tank cost curve; i.e., the way the cost varies with size. If you have a particular hydrogen tank in mind, you can enter its size and cost. Click the Click to add new item option to add more rows to the table.

In the example above, a 1 kg tank costs $1,400 initially, $1,200 to replace at the end of its life, and $30/yr for operation and maintenance.

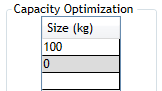

Sizes

In the Capacity Optimization table, enter the hydrogen tank sizes you want HOMER to consider as it searches for the optimal system. Be sure to include a zero size if you want to consider systems without a hydrogen tank.

HOMER uses the information you entered in the Costs table to calculate the costs of each tank size, interpolating and extrapolating as necessary.

Properties

|

Variable |

Description |

|

Lifetime |

The number of years the hydrogen storage tank is expected to last before it needs replacement. |

|

Initial Tank Level: Relative to tank size |

The level of the tank at the start of the simulation as a percentage of the tank size. |

|

Initial Tank Level: Absolute amount |

The level of the tank at the start of the simulation as an absolute amount in kg. |

|

Require year-end tank level to equal or exceed initial tank level |

If you check this box, HOMER considers any system whose year-end hydrogen tank level is lower than its initial level to be infeasible. |

Note: To the right of each numerical input is a

sensitivity button ( ) that allows you to do a sensitivity analysis on that variable. For more

information, see Why Would I Do a

Sensitivity Analysis?

) that allows you to do a sensitivity analysis on that variable. For more

information, see Why Would I Do a

Sensitivity Analysis?